From

to ZETA

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

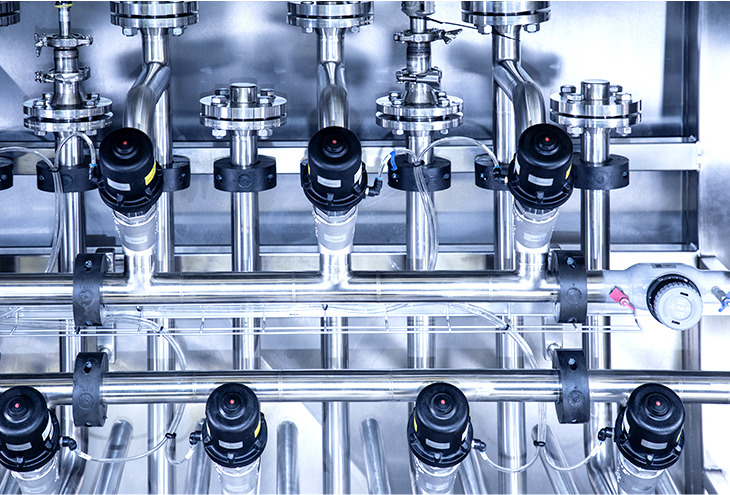

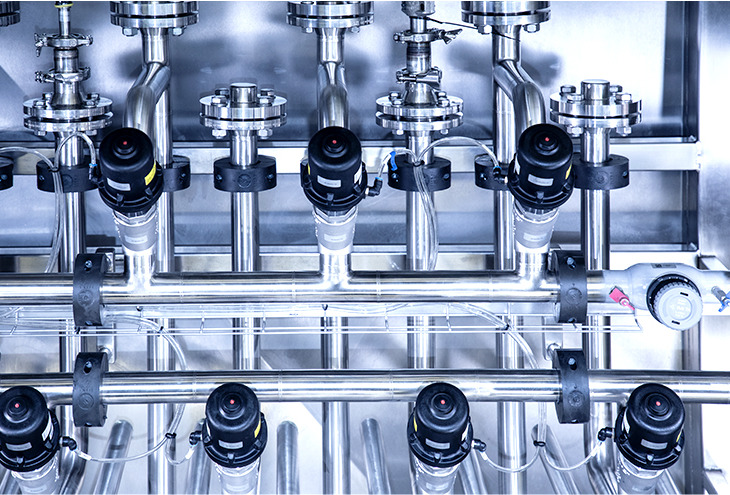

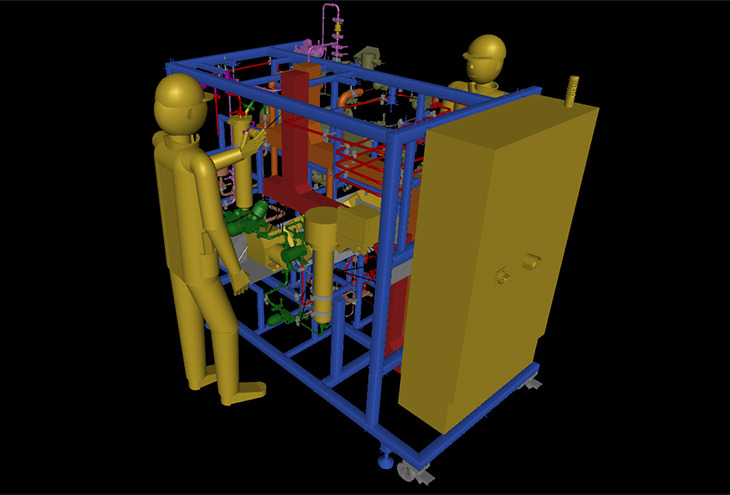

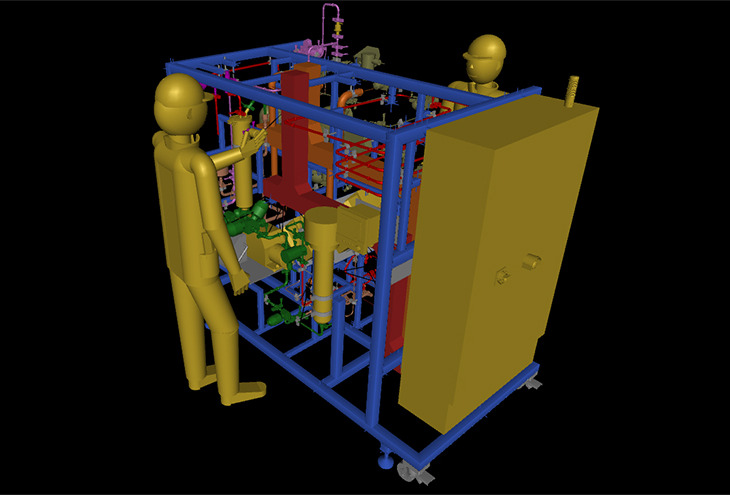

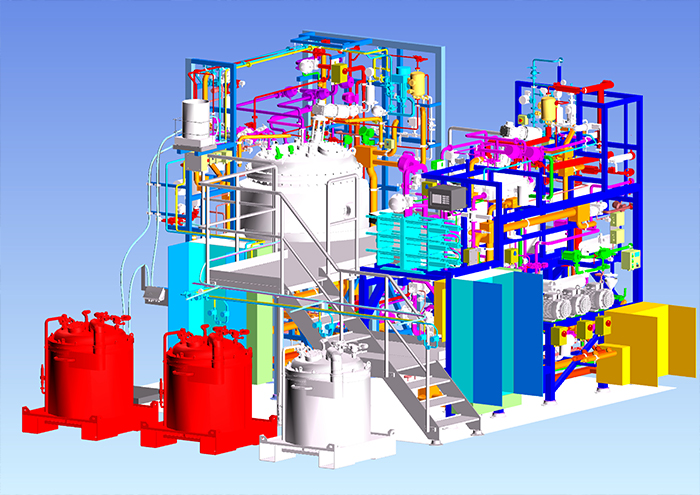

Single-Use Bioreactor Integration

Hybrid bioreactor system combines single-use flexibility with stainless steel reliability.

Custom automation and ergonomic design enable seamless integration of single-use equipment into GMP-compliant biopharma infrastructure.

Stainless steel platform for integration of four single-use bioreactors (50 L, 500 L, 2x 2000 L).

Discover more success stories.