Optimized surface finish for sanitary process equipment

We provide consistent, high-quality electropolishing of stainless steel surfaces–critical for cleanability, corrosion resistance, and long-term performance in pharmaceutical production.

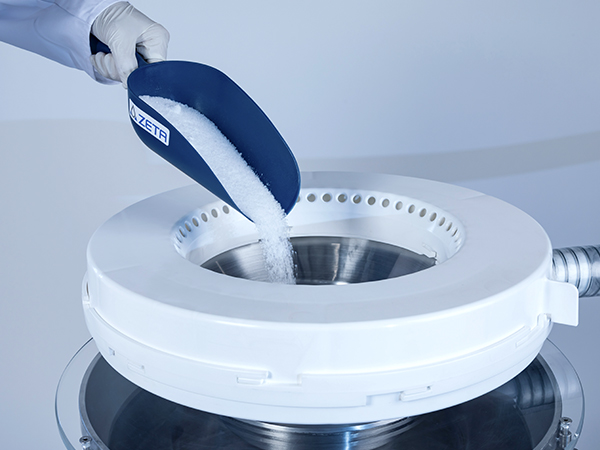

Minimize airborne particles during manual powder addition

ZETA dedusting rings attach easily to existing vessels or funnels, reducing dust exposure by up to 99% and improving operator safety and GMP compliance.

Secure single-use tubing pass-throughs in cleanroom environments

Our mouseholes maintain differential pressure between cleanroom zones while enabling safe routing of single-use hoses through walls–improving process flexibility without compromising cleanliness.

Predictive modeling for fluid dynamics and process optimization

Using Computational Fluid Dynamics (CFD), ZETA simulates mixing, transport, and heat exchange processes in complex systems like stirred tanks, freeze-thaw systems, and high-shear mixing. These simulations reduce trial-and-error during design and help identify process risks early.

Translating ideas into engineered reality

Process development often goes hand in hand with the development of components that add value to (bio)pharmaceutical production. One of our specialities is the manufacture of prototypes of such components.